Drop and hook vs live load: the GPS tracking perspective

When you plan to start your career in trucking, you need to know about some basic jargon. Do you know are the fundamental differences between live load and drop-and-hook? Or, for that matter, which, out of the two, is easier? Which of the two has better earnings if you are a truck driver? Let’s start with the basics.

Drop and Hook

‘Drop and hook trailers’ are the ones that have the routine to be loaded and ready prior to the driver’s arrival. Loads are ready for pickup before the driver shows up at the venue. This has a direct time savings for the driver and the logistics company. As the driver isn’t waiting for the load to be ready, he can spend more time on the road. Similarly, he is not required to wait till unloading gets over completely. He can park the trailer in the delivery yard and move on to his next job. Even some of the shippers or receivers may require the drop to be in the same door as the trailer they are taking. This means that the transaction be termed double drop or double hook. This routine may require extra exercise on the part of the truck driver. However, the process leads to faster turn around times for the driver as the loading and unloading take place rather quickly. In some cases, the company may require an expansive maneuvering where the trailer that is being dropped and the trailer to be pickup next happen to be at separate locations or facilities.

GPS location of Drop and Hook routine followers, help everyone in the line of command fully updated. GPS tracking based on IoT devices helps plan for driver estimated arrival times. This helps everyone in the chain to get in line. Real-time updates help driver position to be shared with their supervisor, supplier as well as end customers. Drop and hook (trailer behind another, shipper running behind, etc.) is preferably a quicker method to get the employee driver back on the road. The more he stays on the road, driving the vehicle, the more he earns for the logistics company. Preloaded trailers allow for the driver to drive in at their suitable time, making it convenient. Hence there is no set dock appointment needed, thereby relieving the stress of having to arrive too late and being turned away. This method is a win-win when a loaded trailer is ready and free of hooking obstacles to the fifth wheel. The overall business operation becomes efficient as well as becomes a profitable way of moving freight.

Live Load

For a scenario where live load is followed, the driver will usually make an appointment to arrive at the loading or unloading facility. The load or unload premises follows scheduling techniques for the deployment of resources. So the driver takes the empty vehicle to the loading doc, vice versa takes the loaded vehicle to the unloading dock. Then he has to wait for the loaders or unloaders to come to the vehicle and start working on it. The driver can not leave the load as is and move to his next assignment. As the worker’s job of moving the freight on or off their trailer gets completed, the driver completes the sign-off and move to the next assignment. The times spent at the docks vary greatly from company to company. A few vendors can do this within 30 to 45 minutes, however, many may take up to 2 or more hours to finish the job. This varies basis the type of loads. There can be bulky cargo that can only be lifted with forklifts or other mechanized vehicles. And alternatively, it could be small boxes of different sizes that require manual labor. Some companies like Amazon even deploy conveyors that can literally be taken deep inside the trailer to speed up the loading and unloading process. The motile conveyor belts go deep inside trailers to assist the labor working inside to finish the job quickly.

GPS location tracking of drivers lets their employers know for how long they had to wait at the docks. Apart from hourly pay, the drivers get compensated for waiting times at lower pay rates. Although it is not a good situation for the driver as well as the logistics services company, it is a common practice for few industries. So while the driver sits in his cab, his work clock keeps on ticking for minutes and sometimes for a few hours of their day. The waiting costs are generally reimbursed by the client company, however, this is detrimental to the driver as they may be earning much more per hour driving than waiting at the docks.

Geofencing provided by the IoT device son board the trucks help the companies keep a minute by minute tracking of the vehicle movement and stagnation. Also, as soon as the vehicle drives out of the set geographical parameters, all the stakeholders get notified.

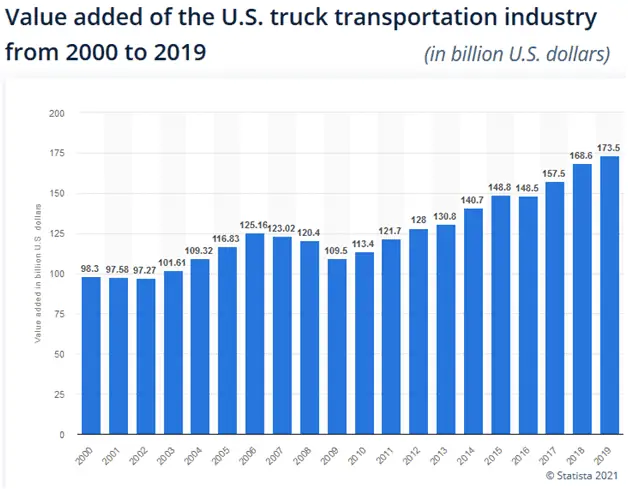

Data chart

Source: https://www.statista.com/statistics/255566/value-added-of-the-us-truck-transportation-industry/

Common Challenges drop and hook vs live load

Drop-and-hook involves learning how to line up the fifth wheel with the kingpin on the part of the driver. Drivers will need to repeat a few times to become experts, it takes some practice before it becomes instinctive. Newer drivers will need to properly use their mirrors and understand the movement and positioning of the rear tires, as in where they should be in relation to the trailer’s width. They may need to stick to GOAL (Get Out And Look) practice a few times initially. As new drivers try their hand at this, they may seek help of fellow experience drivers as they do this. Helping hands come in handy in tight positions were backing up and aligning the trailer with respect to the surroundings is a challenge.

There can be situations where the overall parking premises is not big enough to accommodate multiple trailers sitting and waiting around in their yard. Sometimes the vendors who offer drop or hook facilities may require a switcher or “yard dog” to facilitate your t0railer in and out of the doors.

Drop trailers from a logistics company can be a costly proposition. The trucking company may need as much as twice or three times the trailers to continue operations at the drop and hook facility.

Situations where a loaded trailer is found stashed behind other trailers in the loading area. This ia common phenomenon where the facilities are small and the traffic is relatively high. Finding the people responsible in order to make the trailer accessible can become a bit of a challenge for the driver. The driver may even find it frustrating wanting to get back on the road. Such a situation does not leave much with the driver but to wait and stay calm.