The Evolution of Cold Chain Monitoring Technologies

A Comprehensive Analysis of Data Loggers, Bluetooth Temperature Sensors, and IoT Solutions

Cold chain monitoring technologies have evolved significantly over the years. In this article, we will explore the development of these monitoring technologies in detail, focusing on temperature data loggers, Bluetooth temperature sensors, and IoT solutions. We will examine their benefits and drawbacks, and discuss their impact on cold chain management.

Temperature Data Loggers: Cold Chain Visibility 1.0

Temperature data loggers, or simply data loggers, have been a staple in cold chain monitoring for decades. They provided the first major sensor revolution, giving shippers temperature audit trails for shipments at warehouses and in transit. However, they come with several limitations.

How Temperature Data Loggers Work

Temperature loggers use thermistors or thermocouples to sense and record the temperature at regular intervals. They have a storage memory that records data at set intervals, typically every 15, 30, or 60 minutes. Some data loggers also capture humidity levels. Once the shipment is complete, data can be extracted by connecting a USB data cable to the temperature logger.

Despite their usefulness, data loggers have several drawbacks, including:

- Lack of real-time visibility: Data loggers only provide post-shipment trails, meaning you can’t take action to rescue or replace shipments in real-time.

- Manual effort required for data extraction: Data loggers require physical touch, such as using a USB cable, to extract data at the end of a trip.

- Infrastructure requirements at the receiving warehouse or station: Receivers need a data cable and specific software installed on their systems to read the data from the logger.

- Software incompatibility issues: Each brand of data logger has its own software, and incompatibilities can cause delays and other issues.

Bluetooth Temperature Sensor Beacons: Cold Chain Visibility 2.0

Bluetooth Low Energy (BLE) Temperature Sensor Beacons or Bluetooth Temperature Sensor Beacons are a more advanced solution for cold chain monitoring. These small, keychain-sized devices work similarly to data loggers but offer wireless data extraction and additional features.

Bluetooth temperature sensors improved on data loggers by offering touchless data extraction. However, they still fall short in providing real-time insights. This article provides a detailed comparison between Bluetooth temperature sensors and IoT solutions.

How Bluetooth Sensor Beacons Work

Bluetooth temperature sensor beacons use BLE technology to log and transmit data more efficiently than data loggers. They require a gateway hotspot, such as a smartphone or a dedicated device, which receives the sensor readings and uploads them to a cloud server using data plans or Wi-Fi.

Bluetooth temperature sensors offer several advantages over data loggers:

- Touchless solution: Bluetooth temperature sensors enable wireless data extraction, reducing manual effort.

- Lower detention at destinations: The touchless nature of these sensors reduces delays in data extraction, streamlining the receiving process.

- No infrastructure requirements at destinations: Receivers only need a smartphone or a compatible gateway device to extract data.

- Ability to extract data mid-trip: Bluetooth temperature sensors allow for data extraction during the trip, if needed.

- However, Bluetooth temperature sensors still do not provide real-time shipment insights, limiting their usefulness in proactive cold chain management.

IoT for Real-time Monitoring: Cold Chain Visibility 3.0

The Internet of Things (IoT) offers a revolutionary approach to cold chain monitoring, providingreal-time, actionable insights for cold chain professionals. By leveraging IoT technologies, managers can be more proactive in addressing potential issues in their cold chain operations.

What Can Real-Time IoT Monitoring Do for Your Cold Chain?

Real-time cold chain monitoring enables you to move beyond auditing to problem-solving. With IoT-based solutions, you can gain insights into the location and condition of your shipments and goods, as well as identify potential risks of spoilage, contamination, or theft.

To implement an IoT solution for your cold chain, you can start with a Bluetooth temperature sensor and build upon it. A robust IoT solution should cover data collection, analytics, and connectivity to facilitate prompt decision-making.

Turning Bluetooth Temperature Sensors into a Real-time IoT Solution

Building an IoT solution for your cold chain application involves several components. First, you need a portable gateway hotspot that resides with the goods in a warehouse or travels with them, transmitting the data collected by the Bluetooth temperature sensors.

Next, you need reliable connectivity to relay data promptly for decision-making. Finally, data analytics is crucial to make sense of the collected data and inform actions to take in different situations.

By combining real-time location and condition sensing with predictive analytics and blockchain technology for secure chain of custody, you can gain complete control over your cold chain. This allows you to make smart decisions, such as:

- Re-shipping before a product arrives damaged.

- Dispatching emergency crews to fix a cold chain gap at a warehouse or in your logistics.

- Changing the thermostat setting to compensate for excursions that happened during one part of the journey.

- Re-routing your consignment.

- IoT and blockchain technologies enable always-on, touchless, wireless, transparent, and secure cold chain operations.

The Investment Required for an IoT Solution

To help enterprises adopt proactive cold chain monitoring at a low cost, some companies have developed pay-as-you-go services that remove the complexities of IoT from a user perspective. These services typically include parcel-level cold chain visibility solutions, offering businesses an affordable and scalable way to enhance their cold chain management.

IoT and Cold Chain Monitoring in Various Industries

IoT solutions have found their applications in various industries, enabling them to benefit from improved cold chain management. Here are some examples:

- Pharmaceutical Industry

- IoT-enabled cold chain monitoring is crucial for the pharmaceutical industry, where temperature-sensitive drugs and vaccines must be stored and transported under strict temperature conditions. With real-time monitoring and analytics, companies can ensure compliance with regulations and reduce the risk of compromised product quality.

- Food and Beverage Industry

- The food and beverage industry relies on cold chain management to maintain the freshness and safety of perishable products, such as meat, dairy, and produce. IoT-based solutions help monitor temperature and humidity conditions during storage and transportation, enabling timely intervention to prevent spoilage and ensure product quality.

- Chemical Industry

- Some chemicals and reagents require strict temperature control during storage and transportation. IoT-enabled cold chain monitoring ensures that these sensitive materials are kept within acceptable temperature ranges, minimizing the risk of degradation and ensuring the quality and effectiveness of the chemicals.

- Electronics Industry

- Certain electronic components are sensitive to temperature fluctuations and may be damaged if exposed to extreme conditions. IoT-based cold chain monitoring can help electronics manufacturers and distributors ensure that these components are stored and transported under appropriate temperature conditions, reducing the likelihood of product damage and warranty claims.

Future Trends in IoT and Cold Chain Monitoring

As IoT technologies continue to advance, we can expect further improvements in cold chain monitoring capabilities. Some future trends include:

- Integration of AI and Machine Learning

- The integration of artificial intelligence (AI) and machine learning algorithms into IoT-based cold chain monitoring solutions will enable more accurate predictions and automated decision-making, enhancing operational efficiency and reducing the likelihood of human error.

- Advanced Sensor Technologies

- The development of advanced sensor technologies will allow for the monitoring of additional parameters, such as gas concentrations and light exposure, providing a more comprehensive view of the conditions affecting temperature-sensitive goods.

- Enhanced Connectivity

- As 5G networks and other advanced connectivity options become more widely available, real-time data transmission will become even faster and more reliable, enabling improved decision-making and faster response times.

- Increased Adoption of Blockchain

- The growing adoption of blockchain technology in supply chain management will lead to more secure and transparent cold chain operations, facilitating trust and collaboration among stakeholders and simplifying regulatory compliance.

Final Thoughts

Cold chain monitoring technologies have come a long way since the days of temperature data loggers. The emergence of Bluetooth temperature sensors and IoT solutions has revolutionized the way businesses manage their cold chain operations, providing real-time, actionable insights that help minimize risks, reduce costs, and ensure the integrity of temperature-sensitive goods.

As IoT technologies continue to advance, businesses should stay informed about the latest trends and developments to make the most of these innovative solutions. By embracing IoT-based cold chain monitoring, companies can optimize their operations, protect their products, and ultimately, better serve their customers.

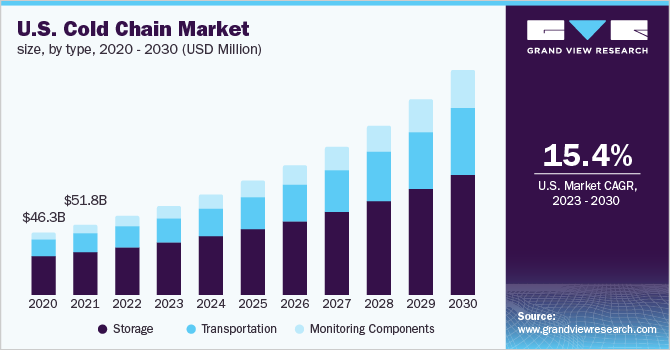

Data Chart: Global Cold Chain Market Size from 2018 to 2026 (USD Billion)

Cold Chain Market growth

Source: Meticulous Research