M2M vs. IoT vs. IoE – know what’s right for you with this industry overview

M2M, IoT, and IoE are indeed disruptive technologies, each to its own. They have had their share of runs with companies adopting them as part of their operations. It is interesting to note the level of innovation and advancement that has taken place in the field of connected technologies. The Internet has been a significant driver for such unprecedented growth. The very term “Internet of Things” was established by Kevin Ashton, a British entrepreneur, in 1999. The phrase meant that the devices would not require human intervention in order to interact and share data with each other. The data exchange will, however, be fully automated.

The advent of similar sounding terms like Internet of Everything (IoE) and Machine-to-Machine (M2M) communication may sound confusing to customers. We take up each topic individually and try to breakdown their relevance and inherent advantages.

Internet of Everything (IoE)

Makes sense to start with the tech, which has evidently the largest ambit over the other two technologies. During Cisco’s endeavors at their entry into a newly emerging field of communications between different devices, the term was coined. The expanse of IoE is vast. It covers almost all the devices that have the capabilities of communicating with other devices. This communication happens without the involvement of humans. The four elements that have played in IoE are as follows.

People – Of course, humans will always be at the end-user point in the chain. The sharing of information between devices happens with the sole purpose of making the lives of humans easier. Devices pass information among each other to take away human labor efforts and accomplish the jobs in the most efficient and timely manner.

Things – The devices themselves are the critical element of this ecosystem. The devices are generally the points where information is generated and stored. Such devices include sensors, devices, actuators, and other items. Data is either originates from these devices or is being transferred on to. They process the data and take requisite actions.

Data – Data itself is like the blood running throughout the body. It is the single uniting factor among all other elements of the IoE ecosystem. Raw data gets generated at devices like temperature sensors, accelerometers, humidity sensors, etc. It is then passed onto an onboard processing module or transferred over to cloud servers. Based on the processing of this data, the devices take decisions and carry out jobs independently.

Process – This element puts things into perspective. The steps are laid out, rules are defined for the devices to follow. When data is recorded, it flows through different steps of the process, and things get done.

IoE has the largest of ecosystems, and it connects end-to-end. It integrates technologies, devices, data, processes to execute work all the way.

Internet of Things (IoT)

Internet of Things literally means that the things (devices) are interconnected. They can independently talk to each other. These devices are embedded with sensors, control systems, and processors that will enable a horizontal line of communication. As IoT continues to evolve, more devices will become smart and remove the human intervention.

A perfect IoT driven system will bring harmony to processes and operations across organizations. They will bring an evolved sense of Safety, Comfort, and Efficiency. More availability of data will mean better decision making. Hence reduce costs significantly. A supply chain that involves use of supply chain connected devices typically has more ‘things’ interacting with ‘things’ than just human interactions. The product interacts with its outer packaging. In turn, the outer packaging interacts with material handling equipment, transport vehicles, storage facilities, etc. There are so many interactions from the moment the product comes into existence to its final consumption destination. Hence there is a need to record and trace these interactions. Perhaps monitor them for any abnormal circumstances. This is where IoT forms the critical element of a connected chain and supply chain management device. IoT involves the use of sensors, recorders, transmitters, etc. These are fitted to handling equipment like pallets, containers, forklift trucks, and transport vehicles.

Shenzhen Eelink Communication Technology Co Ltd is a prominent name in GPS tracking and IoT manufacturing. Their most advanced DB01 BLE Temperature & Humidity Sensor Beacon models have a long battery life that lasts up to 3-years. It is definitely the most economical beacon in the market.

Machine to Machine (M2M)

Machine to Machine literally means point-to-point communication between physical-first objects. M2M technologies are also described as enablers of communication between machines without human intervention. The benefits of M2M outnumber several other technologies. They start with bringing about a significant reduction in costs. M2M brings in efficiency by way of automating tasks. Machine involve one-time replacement cost, however, they prove economical in the longer term.

M2M literally works round the clock 24 hours a day, 365 days a year. Data is made available in real-time, supported by device related alerts. Users have meaningful information available to them through the dashboard. A single integrated cloud-based platform for performance management. Such information is accessible on smartphones, tablets or even desktop computers.

Another feature of M2M is that it is highly scalable. So it can grow with your time as your business grows in size. With M2M working in your favor, it is time for you to focus on priorities. As most jobs are automated, the business owners can set their preferences and focus on them. Security is an inbuilt feature across all major device-to-device technologies. M2M also boasts of platform security and data encryption.

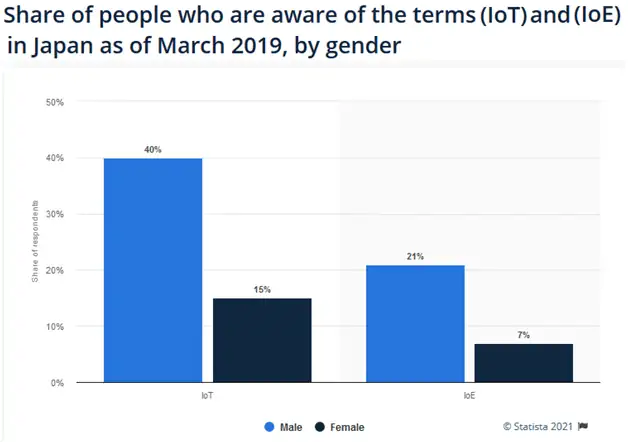

Source: https://www.statista.com/statistics/1058412/japan-awareness-iot-and-ioe-by-gender/

Influence of technology on business and clients

As you went throughout the article, you would have developed a better understanding of each of the concepts IoE, IoT, and M2M. Knowledge is the main driver for adoption. Especially when you as a business owner find yourself finding the absence of support in the form of government regulations. The speed of evolution of these technologies has left governments and regulators in limbo. Add to it the rapid changes in consumer expectations and behavior.

Businesses will have to evaluate each of the technologies independently. We present a use-case for IoT devices in the cold supply chain. The deployment of IoT makes cold chain sensors intelligent. The cold cargo is equipped with sensors that record and monitor the temperature throughout the chain. They keep a tab on the temperature as per range requirements and maintain the items within acceptable temperature limits. In case of any breaches in temperatures, the IoT cold chain sensors enable monitoring devices to send notification alerts to the stakeholders. The driver is the closest person in the chain of command, can heed the notification and immediate action. Sensors also track the GPS related movement of goods and stay connected to the overall network running the supply chain ecosystem. Learn more about IoE, IoT, and M2M solutions