Managing Your Cold Chain Logistics in Real Time

Although globalization and technological advancement have figuratively made the world a smaller place, any business that functions with a cold chain supply system will be able to tell you that physical separation between the supplier and consumer is still a very real problem. Cold chain logistics involves the logistical planning of the transport of any temperature sensitive product over long distances through the use of thermal and refrigerated packaging methods, that ultimately ensures the integrity and quality of the products. This is most frequently used in the food and pharmaceutical industry, due to extreme sensitivity of their products.

Whether you are transporting your products by road, sea, air or rail, the true challenge lies not in securing a proper temperature controlled form of transport for your product, but indeed in the monitoring of these transport systems. The fact remains that temperature control systems can fail, or malfunction and ultimately result in the perishing of your goods. This will naturally cost you money and may even cause the loss of clients.

This is exactly why real time cold chain logistics management is so important, especially in a competitive business climate. Cold chain management involves finding the delicate balance between maximizing products safety while minimizing cost and real time management is the solution to this problem. In order to manage your perishables in real time, you would need real time temperature and humidity sensors attached to your cargo.

Types of temperature and humidity sensors

Shipment monitoring started with GPS tracking of cargo while they were in transit, and while this is still vital in many cases, the addition of temperature and humidity sensors to this system has added an extra dimension that upped the cold management game.

These sensors all serve the main purpose of alerting you to any changes in the temperature or humidity in the immediate surroundings of your product. Any temperature or humidity fluctuation will be recorded or even reported in real time, so any mishaps or breakdowns can be regulated and fixed immediately, thereby preventing loss and ultimately minimizing cost.

Data loggers

These are some of the earlier sensors that were added to shipments and could actively record any changes in temperature and humidity, but were unable to report this data in real time. They were very useful for tracing problems in the shipment route or plan, and can also be used by customers to determine if products are safe for use. This is especially valuable for medicines and vaccines, that will show no obvious signs of inactivation due to increased temperatures. Data loggers did however not offer much aid in terms of active prevention of shipment damage or decay, and modern systems are now able to provide all the benefits of data loggers along with real time reporting and response.

Bluetooth sensors

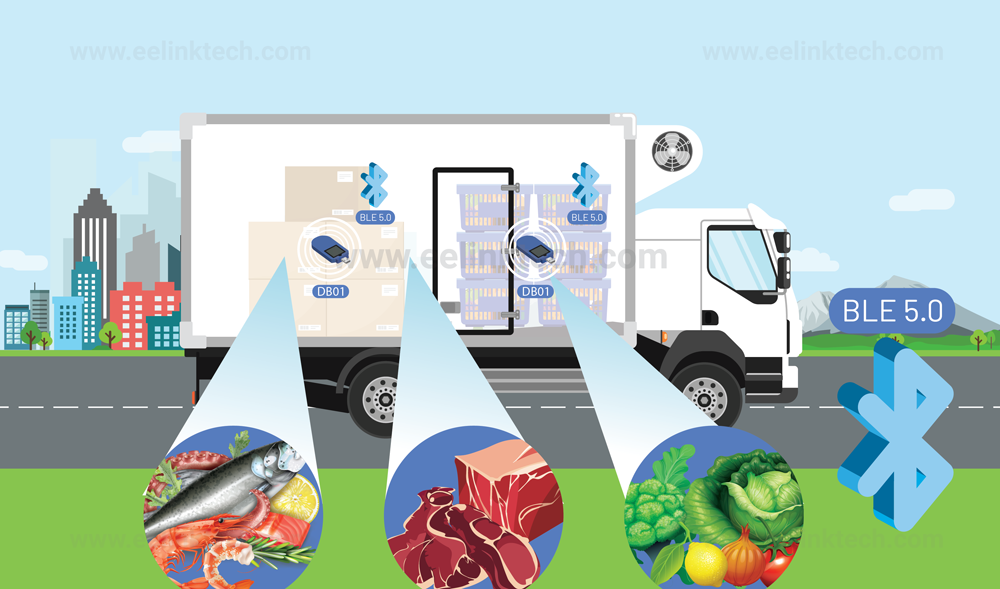

After the long term use of data loggers, Bluetooth sensors were developed that could actively track and report a whole range of additional data besides GPS locality. Bluetooth Low Energy (BLE) or Bluetooth Temperature Sensors can offer touchless data extraction once a route has been completed, so you can, through the use of a wireless device such as a cellphone, extract data for evaluations. By themselves, Bluetooth sensors can however not report data in real-time even though they offer the added benefit of easy data extraction.

IoT systems for real-time traceability

Naturally, with the advancement of technology and internet service, data loggers and Bluetooth sensors could be connected to real-time reporting systems that enabled fast data logging, reporting and actionability in terms of problems encountered. Although data loggers and Bluetooth sensors do enable you to trace you shipments condition after the trip or a segment of the trip has been completed, they do not allow you to actively prevent spoilage due to temperature and humidity fluctuations.

Only real-time systems can do this, and provide suppliers with the added benefit of decreasing hands-on time and responding to possible events before they become a problem. The beauty of IoT (Internet of Things) systems is that they are simply an expansion of Bluetooth systems by incorporating a real-time connectivity to a stationary reporting system that can send alerts when temperature or humidity fluctuates above or below a specified range. Once an alert is sent – the responsible personnel will simply activate an action response plan to determine if the alert is a real problem, and then to deal with it by setting a plan in motion to have the shipment moved to another container or truck that is functioning.

The beauty of IoT systems is that with very little effort, you existing Bluetooth sensors can be converted into a IoT systems with the addition of a few simple components. In these systems, a simple conversion of the cellphone connected to the Bluetooth sensor will allow a program to link to a base unit at the warehouse or main office, that can receive and interpret the signals sent from the Bluetooth device. These programs will can then be programmed to alert the user if fluctuations in temperature or humidity occur.

Alternatively, modern Bluetooth sensors come ready linked to online systems that facilitate real time reporting to a base computer or smart phone at the warehouse of office.

NFC technology

Near Field Communication (NFC) systems is a modern and relatively recent addition to the cold chain logistics management field. Working in a similar manner to Bluetooth systems, NFC sensors communicate via wireless data transfer technology. It carries the advantage in that it is up to 10x faster than Bluetooth. Data form any NFC enabled sensor, that includes shipment information, temperature and humidity log as well as GPS location of the sensor, is accessible to any other computer or smart phone that is NFC enabled. The beauty of NFC data logger is that they come equipped with LED diode that will indicate if the cold chain was ever broken during the transport, providing the customer with immediate reassurance as to the condition of the products.