Significance of supply chain connected devices in connected Supply Chains

With the advent of technology and increasing trade levels between countries across the globe, supply chains are now more complex than ever. Global GPS supply chain networks are so big in size that they can be considered complete Ecosystems within themselves. It comprises logistics providers, suppliers, and customers, all being dependent on each other. As per the data shared in the World Economic Forum report, about 4 million consumer products are made, shipped, and sold around the world each year.

The biggest issue faced by this connected supply chain is ‘Traceability’. The products move from the raw material stage to manufacturing, to consumer, and back to recycling, resale, or disposal. This is where technology use is highly beneficial. Visibility across the supply chain is significant. It is not merely aimed to find and know where the goods are along the chain. It involves the bigger issues like optimum use of resources in businesses. They include inventory management, product development, agility, and pricing. Last but not least, it also aims to improve customer service. The persons involved in decision-making study customers’ buying patterns, the location where these orders are being placed, how the items are treated while in transit, and ultimately, when they will reach the destination.

Technologies supporting a connected Supply Chain

The best digital technologies that play a critical role in connected GPS supply chains include the following.

Internet of Things (IoT)

A supply chain that involves use of supply chain connected devices typically has more ‘things’ interacting with ‘things’ than just human interactions. The product interacts with its outer packaging. In turn, the outer packaging interacts with material handling equipment, transport vehicles, storage facilities, etc. There are so many interactions from the moment the product comes into existence to its final consumption destination. Hence there is a need to record and trace these interactions. Perhaps monitor them for any abnormal circumstances. This is where IoT forms the critical element of a connected chain and supply chain management device. IoT involves use of sensors, recorders, transmitters, etc. These are fitted to handling equipment like pallets, containers, forklift trucks, and transport vehicles.

B2B platform for interactions

As the product moves through the supply chain, it moves from the hands of one business to others. And the supply chain connected devices play an important role. A standard, well integrated B2B platform is like a backbone to a connected supply chain. We observe an elaborate cloud-based infrastructure that works with several processes and applications covering various aspects of the chain.

Dependence on AI/machine learning

Artificial Intelligence (AI) is more relevant to supply chains than ever before. The predictive analytics capabilities of AI are now integral to the success of a connected supply chain. It consumes the data generated at various levels in the chain to give out meaningful insights. Which is critical to planning and forecasting. Machine Learning helps deploy analytics to enable automation of several steps of the GPS supply chain.

Problems faced by stakeholders of connected supply chain

The products moving through the supply chain change hands several times through their moving process. This leads to a lot of interdependence between stakeholders. The movement is so linearly connected that sometimes one small delay can render the rest of the chain completely worthless. Hence there is a need to synchronize manufacturing, movement, and consumption.

IoT plays a pivotal role in addressing regulatory and compliance standards. It is also critical to visibility and traceability throughout the supply chain. An efficient IoT-driven supply chain and supply chain management device can help withstand pressures from competitors and ensure efficiency.

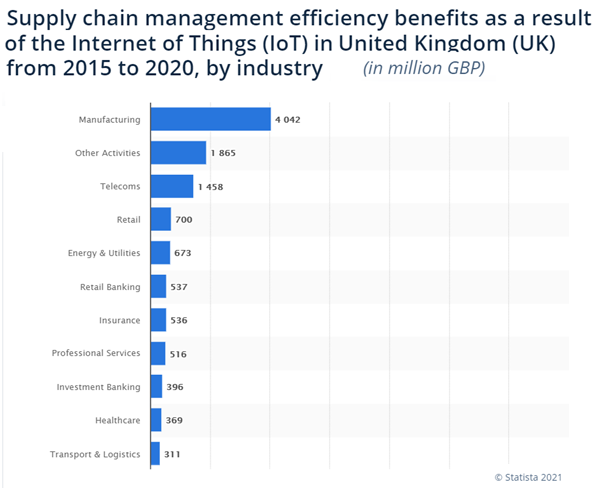

Source: https://www.statista.com/statistics/608357/iot-supply-chain-management-efficiency-benefits-uk/

The supply chain asset management solution developed by Shenzhen Eelink Communication Technology Co Ltd is the most unique product in the market. It is a wholesome offering where the assets can be tracked easily using the best in-class GPS and sensor logistics solutions. It supports the users with its 3 significant pillars of service:

- Risk mitigation across the supply chain

- Complete removal of blind spots

- Quicker issue resolution with a prompt response

Eelinktech Asset Management solution provides the ability to track the supply chain component’s movement, location, and condition. The system can easily keep track of the variable aspects of the product. These include humidity, temperature, fall-detection, and changes in lighting. It also provides users with advanced capabilities like geotagging and geo fencing, where custom notifications are received when the product moves out of a particular defined geography.

The Eelinktech Asset Management – Operations Center is your one-stop solution for tracking needs. You can customize almost all the aspects of the movement of your goods throughout your supply chain. Once the assets are connected to the system, they are tracked relentlessly throughout their life in the supply chain.

Most prominent features of Eelinktech Asset Management

· Multiple connections capabilities – The equipment is able to work with several connection technologies like LTE/LTE-M/NB-IOT/satellite/Wi-Fi/BLE devices.

- High precision GPS and GLONASS – These high accuracy positioning systems use a 72 channel high sensitivity receiver for pinpoint positioning.

- Full track of historical movements – Tracking of items with the added capability to know the variables like temperature and humidity went out of bounds for specified ranges. So in case, there is a dispute with any stakeholder, the variances records can easily be pulled out of the system.

- A multitude of support capabilities of system and equipment – Devices and equipment provide support like tracking of location, temperature, humidity, motion detection, and ambient light intensity.

- Fall or impact detection alerts – Alerts are sent whenever g-forces exceed the set ranges

Prominent benefits of Eelinktech asset Management

- Extended battery life that lasts up to 5 years on a single charge

- IP67 rated device housing provides for water and dust resistance

- Issues addressed on a real-time basis, thereby monitoring and intervention for critical issues

- Adaptive tracking capabilities that send out smart notifications only when movement occurs

- Geo fencing for quick retrieval of location data

The purpose of connected supply chain

A lot of strategic decisions are based on the working of a GPS supply chain. As supply chains involve a lot of variables, they come across a lot of competitive differentiation too. The primary purpose of a connected supply chain is as follows:

Unique Visibility and Traceability advantage – When the whole ecosystem is interconnected, it is easier to locate the traveling goods. And if you face issues with previously delivered items, you only need to pull out the logs and get to the most critical point. Pulling logs out is as easy as clicking a button. This also acts as a driver for an enriching customer experience.

Agility and versatility – Agility is the name of the game when dealing with competition. When you have real time operation updates, there is so much you can do. And at the same time match customer’s demands. Connected Supply Chains provide unparalleled agility to run a demand-driven business.

Supply chain optimization – The connected supply chain is always the most efficient chain. It can fully utilize available resources and bring in the much-needed scope of optimization and improvement. And it reduces the costs in the process. Customers have the option to log into the system and see the status of their shipments. This helps them plan ahead for their business operations. Thus, leads to a stronger relationship for a long-term symbiotic growth plan.

Benefits of IoT-driven connected supply chain

To make sense of the discussions above, here are the most significant benefits a connected supply chain provides. They definitely make you ponder towards making a decision to make the shift.

· End-to-end visibility – Real-time Visibility and traceability are the hallmarks of a connected chain and supply chain management device for all users, including the multi-modal 3PL providers.

· Increased level of automation – Leads to less human error and overall operational efficiency. You and your customers have access to real-time updates on inventory levels and consumption patterns.

· Avoid disruptions – With all the chain steps being connected, you can quickly identify issues and resolve them before they grow out to uncontrollable proportions.

· Efficiencies in operation and RoI – With an IoT-driven framework and tracking features, the investment turnaround periods are shortened. Shippers can plan complex shipment networks within the ecosystem and manage them efficiently.