Temperature sensors help maintain the usefulness of COVID-19 vaccines

Our scientists and pharma companies have cleared the first challenge of creating the vaccine for COVID-19. The next hurdle is to get the vaccine out there to the population. The challenge is to keep the vaccines potent as they are moved across continents while maintaining the stringent temperature conditions. Once they achieve the hard target of manufacturing millions of doses, these need to be moved to the affected populations. Another challenge is that the vaccine works with two injections. Once the millions of doses are made, they need to be maintained at extremely cold temperatures. It is imperative to use best in class temperature-monitoring tech that has the best connectivity options. It is advanced enough to handle all possible hindrances in the movement.

The vaccines for COVID-19 are one of the fewer pharmaceutical items that need extremely low temperatures for storage. In case there is a fluctuation in the Pfizer vaccines’ temperatures, it will lose its potency. The movement from the manufacturing facility all the way to the far-flung locations around the globe is a big challenge. Having small temperature sensors fitted on to the consignments is going to be an excellent idea to maintain this critical vaccine. The vaccines can be conveniently stored at factory premises because they have the necessary infrastructure available to do so. However, when they move the vaccines, various locations and routes have varying weather conditions. The journey is long, and there will be a need for storage at the location where the vaccines will be inoculated. These places will generally be hospitals as they still have some infrastructure to maintain the strict temperature ranges. However, at locations where no such temperature controlled facility is available, the plan would be to keep the vaccines in the truck or other freezer equipped vehicles. The vaccine vials will be packed into freezing containers, which in turn will be held in freezer boxes and then loaded on to the vehicles. The GPS temperature monitoring devices for COVID-19 vaccines will need to maintain intensive temperature monitoring. This is definitely something that we could not envisage 5 years ago.

Rapid technological advancements have made subzero storage possible. Our generation is lucky to have these advancements that have made it possible to develop, manufacture, and move the vaccines around the globe. These innovations have proved useful in saving endless human lives and spared country economies. Covid has already wreaked havoc on every economy across the world.

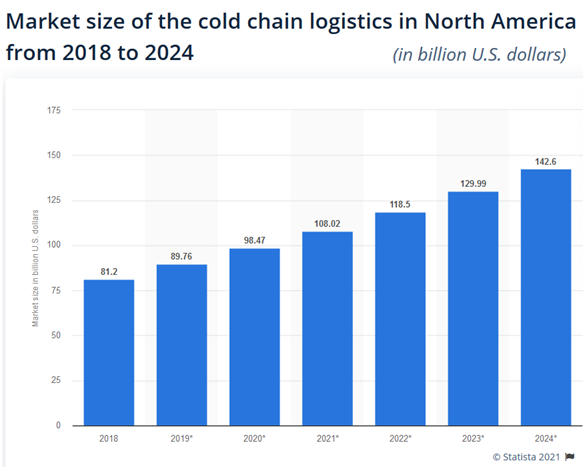

Source: https://www.statista.com/statistics/955108/cold-chain-packaging-us-market-size/

As the manufacturers make investments in improving their manufacturing capacities, logistics providers focus on expanding their networks. Upgrading their vehicles with the latest low temperature movement capabilities. The product for temperature monitoring, vaccines cold chain temperature monitoring devices based on IoT technology is already available in the world. Read more about it in our blog article. The DB01 Bluetooth temperature and humidity monitoring beacon is a boon for the temperature sensitive logistics businesses.

The movement of the Covid-19 vaccine is super critical. We can not afford to lose a single vial. Every last drop of the vaccine needs to be potent enough to help save lives. Under the normal circumstances, it is understood that one-fourth of vaccines are wasted in the movement and storage operations. The current vaccines for COVID-19 mandatorily need to be stored at low temperatures. In particular, the Pfizer vaccine must be held at around -70 degrees Celsius (-94 degrees Fahrenheit). Fluctuations in temperature will mean rendering the vaccines useless. If there is a breakdown in transit and the temperature is not maintained, the cargo will be of no use. Such ultracold temperatures need to be maintained throughout the supply chain. This is where the monitoring becomes super important.

The mere use of temperature data loggers will not be of much help. As they will log the changes in temperature but not take necessary action. The IoT enabled connected COVID-19 vaccines cold chain monitoring devices log the temperature and actively report the fluctuations to all stakeholders. And this reporting is done on a real-time basis. Starting from the person closest to the cargo, i.e., the driver, to the administrator, dispatcher, as well as the clients.

About a decade ago, when such advanced devices were not available, the personnel would have to check the temperature manually. This would mean opening the truck storage compartments, opening the freezer boxes, and even opening the cold shipper packing boxes. Opening these would have a negative effect on temperatures and the compressors. Machinery would have to work double-time to retain the cold ambiance. Digital devices can be fitted onto each cargo unit to continue monitoring. Their extended battery life of up to 3 years enables them to continue monitoring. There is no need to change batteries from time to time.

Companies like Shenzhen Eelink Communication Technology Co., Ltd. have educated customers and helped them adapt to new technological advancements. The article highlighting the importance of using cold chain temperature COVID-19 vaccines cold chain monitoring devices proves to be very educative. Several pharmacies, drug companies, and even clinics have started utilizing these technologies, which sit inside of a freezer or transport container. These devices continuously monitor the temperature inside these units. With IoT enabled devices, there really is no need to physically download the logged data from the devices. You only need to have a smartphone with a Bluetooth connection or even connect your laptop to or tablet to the beacon wirelessly to get the data. The devices have the onboard memory that logs severals of thousands of data reports.

Shenzhen Eelink Communication Technology Co., Ltd. produces the next generation of internet-connected cold chain sensors. These small beacons slot inside transport devices as well as freezers and continuously transmit data on the temperature. This data is shared by the logistics companies to their pharmaceutical client companies and pharmacy managers. They can easily see any event that may occur in the field. Suppose there is something that seems to compromise the integrity of the packaging. In that case, they can come to know about it immediately. And then corrective action can be taken in the nick of time to save the cargo from getting spoilt. Transport of COVID-9 vaccines has no room for errors. The push to automate temperature sensors by Eelink has seen several companies benefit from it.

Apart from CIVID-19 vaccines, there are other gene therapy-related treatments that are temperature sensitive. Hence, there is an enormous scope of application for these advanced IoT devices. Moreover, it is not only the pharma industry that needs to use such ultracold temperature transport and storage. There are other industries too that have started adopting digital and internet-connected monitors. In 2018, the CDC (Centers for Disease Control and Prevention) made it a point for the logistics stakeholders to digitally monitor the Vaccines for Children Program cargo. That was a turning point for pharma logistics service providers.

The devices that monitor temperature need regular calibration to ensure they are reporting accurate temperature measurements. The digital beacons prove super useful in this regard. Distributing COVID-19 vaccines is an uphill task. Digital temperature monitoring devices try to help in the way. The DB01 BLE has the best in class Temperature & Humidity Sensors. Its long-lasting 3 year battery makes it a perfect choice for the most efficient and economic beacon. Shenzhen Eelink Communication Technology Co., Ltd is one of the most popular manufacturers and suppliers of innovative products and solutions. They follow strict compliance with best industry standards in local as well as international markets.

When you link the beacon to the cargo, every box gets equipped with a GPS beacon, a temperature and humidity monitor. For a connected cold chain to be feasible, ti needs to focus on the following three elements:

- Diligent, trained workforce

- Reliable temperature controlled storage and temperature monitoring equipment

- Precise monitoring of vaccine inventory