The complete list of fresh produce logistics challenges (and solutions)

Fresh produce can be raw or processed. It can be constituted by fresh fruits as well as vegetables. They are generally a class of goods that are sensitive to changes in temperature and humidity. The shelf life depends entirely on the maintenance of desirable growth parameters during transportation and storage. Hence the control over the atmosphere during transit is exceptionally critical in retaining the freshness and quality of foods.

Fresh produce comes in various shapes and sizes. They are usually sorted and graded at the first stage of processing and then packed as per varying shapes. Each type needs a distinct treatment when a consolidated attempt is made to retain its freshness and quality. The mechanical cooling equipment involved in maintaining the desired temperature conditions plays an important role. The equipment needs proper servicing to continue to work well. The human error being a threat to the overall quality of the product, can be addressed with appropriate training of personnel involved. Efforts should be targeted on reducing the time the fresh produce spends in transit. In one of their reports, United Nations stated that almost one-third of foods produced across the world are not able to make it to the consumers. The produce gets spoilt either during storage or during transit. A lot of care needs to be put in while transporting fresh produce. It starts from picking the produce that is fit for transport, proper sorting and grading, customized packaging, controlled atmosphere transport, and proper storage.

The tremendous advancements in cooling technology and monitoring technologies have helped in retaining produce freshness. The hi-tech equipment has made it possible to store foods for extended periods, thereby saving a lot of food around the world. IoT has played a pivotal role as a cutting edge technology for the modern cold food supply chains.

IoT in modern cold supply chains

Fresh produce supply chains have successfully achieved sub-zero Celsius temperatures. Fresh produce can not be kept for long at room temperature as it will get spoilt quickly. The refrigerators found int eh households are able to maintain the temperature ranges from 2 to 8 °C (36 to 46 °F). When GPS IoT tracking beacons are deployed, they closely monitor changes in temperature, humidity, and even events of shock. The IoT device tries to reach out to other devices in the network in case of undesirable events. It sends out alerts to the truck driver and other stakeholders. It can also connect through a cellular network and reach out to the logistic company’s cloud network to alert the authorities.

Challenges in steps towards an efficient movement of fresh produce

- Get the right fresh produce

The fruits or vegetables constituting your target cargo should be sorted and graded well before transport. They should be sturdy enough to endure the shipping. They should be free from any damage and bruising, as these things tend to exacerbate during long hauls. The produce that is under-ripe is usually preferred for transport. It has a harder texture than ripe produce, and it has a longer shelf life.

- Getting the right packaging

Custom packaging should be used basis the type of fruit and vegetables being transported. Different packaging should be used for different types of produce in case several different varieties are transported together. Fruits such as apples, citrus, and pears tend to have hard skins. Hence they are good long hauls and are sturdy enough to handle shipping ambiance. Whereas soft fruits such as plums and peaches need more care while packaging to be able to reach their destination in good condition. Another important aspect of the chosen packaging should be how it protects the produce from temperature variations.

- Proper loading and shipping

So you have chosen the right fruit or vegetable, and you found the best fit packaging. The next obvious step in the process is to pay utmost care while loading them onto the vehicles. And later on, ship them under most desirable conditions. The ethylene given off by fruits after being harvested causes them to ripen and spoil quickly. Hence care must be taken to keep them separate from other fruits that get spoilt faster in presence of ethylene. Customized loading and unloading equipment can be deployed that contribute towards improving the overall efficiency of the supply chain.

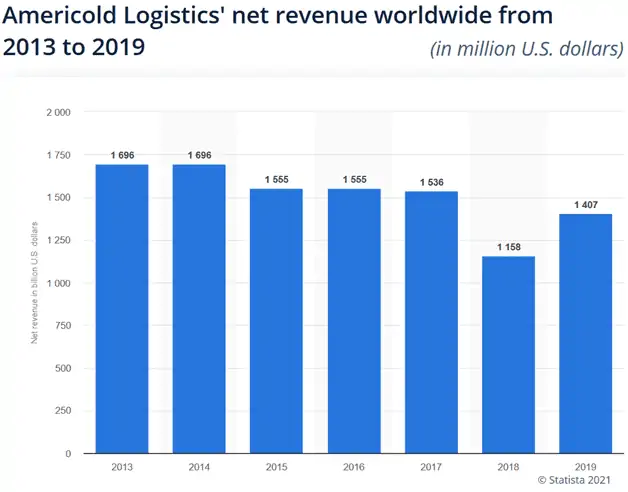

Source: https://www.statista.com/statistics/758693/americold-logistics-net-revenue/

Challenges in transporting fresh produce

The four options for transportation are by air, road, rail, and sea. Air transport is the most expensive option is only preferred in case of high value produce that has a low shelf life. Road option is beneficial for smallest of quantities and less number of days during transit. Rail transportation is preferred for products that need to travel anywhere from 2-3 days. The fresh produce can be kept in insulated or cooled cars to keep it fresh. The economical and perhaps the slowest of all is shipping via sea transportation. It is suitable for produce that has a long shelf life and is usually shipped in large quantities.

Temperature and humidity conditions

Fresh produce is very sensitive to temperature and humidity ambiance around them. Hence it needs to be controlled and monitored to be maintained at desired levels. Whenever the temperatures reach room temperature levels or more, the produce continues to ripen quickly. Another reason to maintain low temperature is to prevent attack from bacteria and other pathogens.

Fruits such as oranges, grapes, and cherries need a storage temperature range from 0 to 2 degrees Celsius and with a humidity range of 95% to 100%. Whereas produce like garlic and onions require the same temperature range but a much lower humidity level at 65% to 75%. Any higher humidity levels will simply spoil the product, even before it reaches its destination. Fruits like bananas, mangos, and even avocados do not do well when temperatures dip below 13 degrees Celsius. Hence, they are kept in the range of 13 to 15 degrees Celsius and between 85% to 90% humidity.

Hence, a great level of customization is involved in picking, packaging, transport, and storing fresh produce.

Damage from impact

A rather common reason for produce damage is caused by impact. This impact can occur anywhere during processing, transport, and storage. Customers obviously will not pick bruised and damaged produce as part of their grocery. So if the product suffers an impact during transit and is damaged, it may get rejected at the customer’s receiving point. Hence care should be taken to observe and secure the produce from shocks and vibrations occurring during shipping. These can end up damaging the produce seriously. A common reason for damage can be that the items are not packaged and loaded properly.

While care is taken at each and every step of the cold supply chain, your efforts can be augmented by the use of an IoT device. It not only monitors the set parameters round the clock, it also sends out alerts in real-time. Thus, the alert signals sent to stakeholders can lead to prompt action and thus prevent spoilage of the fresh produce being transported.